# The Ultimate Bearing Maintenance Guide for the Textile Industry: How Proper Lubrication Powers Bearing Failure Prevention for Industrial Maintenance Indonesia

That tiny, squeaking part deep inside your machinery is not just an annoyance. It’s the sound of your profits evaporating, and it’s why effective bearing maintenance is the most overlooked secret to success in Indonesia's textile industry.

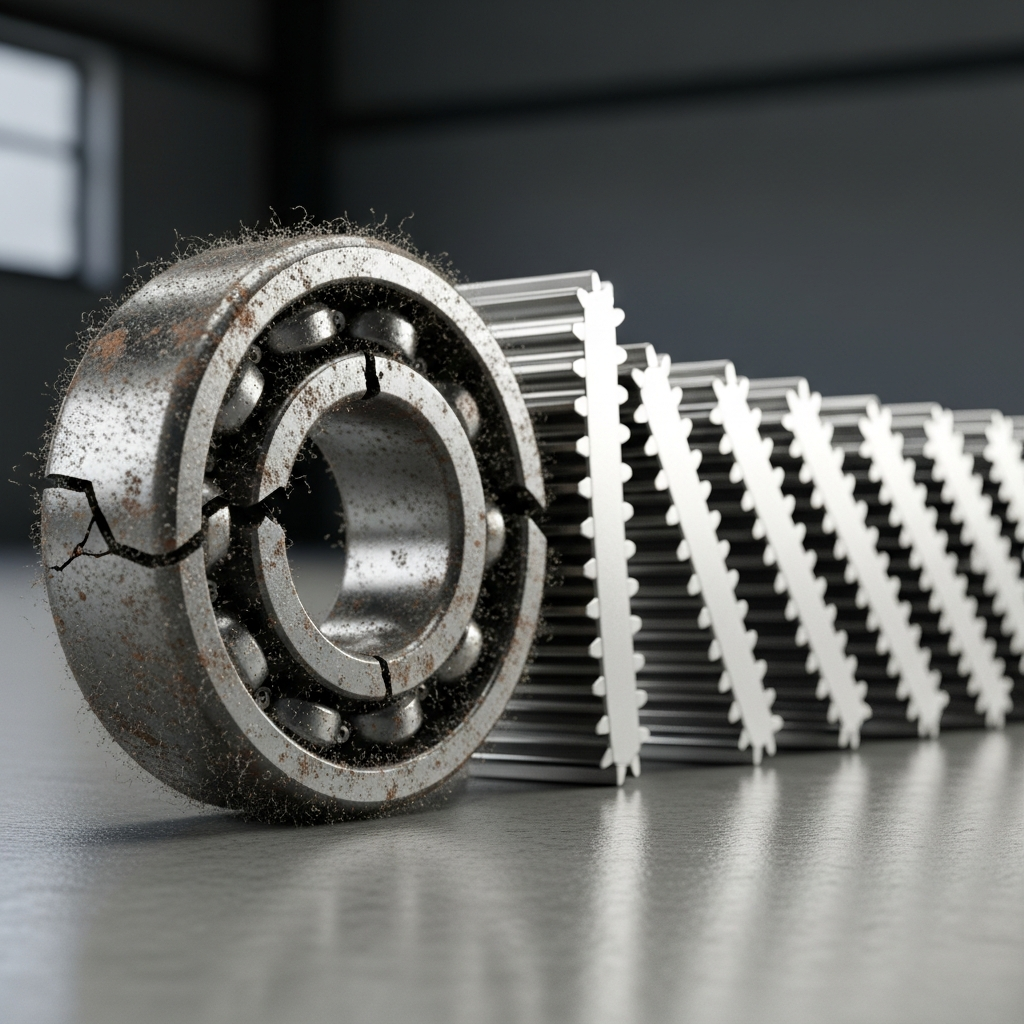

You replace a failed bearing, only for the new one to break down just a few months later. It’s a frustrating cycle of unplanned downtime and wasted money, especially when extreme heat and constant dust attack your equipment. The real problem is rarely the part itself. It's almost always poor lubrication or contamination from cotton fibers.

This guide is your complete blueprint for proactive bearing failure prevention. We're moving beyond just fixing what's broken and showing you how to stop failures before they start.

You will learn why your summer maintenance checklist must be completely different from your winter one and discover the simple sealing practices that keep destructive dust out for good. This is the new standard for industrial maintenance Indonesia, designed to keep your machines running and your costs down.

Introduction: The Hidden Cost of Bearing Failure in Indonesia’s Textile Industry

In Indonesia's fast-paced textile industry, a single failed bearing is never just a small problem. It creates hidden costs that spiral out of control, including expensive repairs, lost production from unplanned downtime, and buying the same parts over and over again because the root cause was never fixed [2][1]. This makes effective bearing maintenance a top priority.

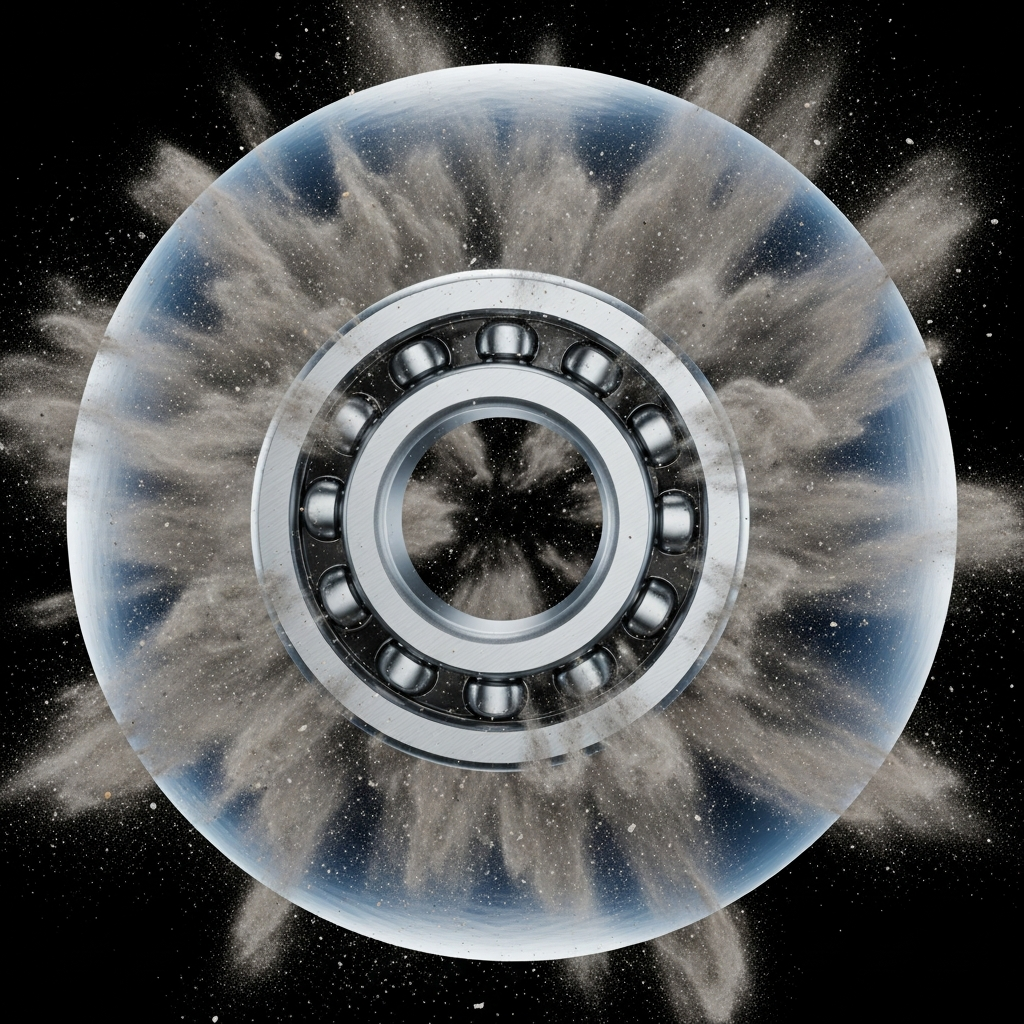

Bearings are the unsung heroes inside spinning machines, looms, and finishing equipment [3][4][1]. They help everything spin smoothly, day in and day out. In massive mills that run nearly 365 days a year, a single bearing failure can shut down an entire production line. Every minute the machines are off, money is lost [2][1]. Proper bearing failure prevention is not just about saving a part; it's about protecting your profits and keeping the entire operation running [1][5].

The challenges for industrial maintenance Indonesia are unique and harsh. Mills operate in environments with:

- Extreme heat

- High levels of dust and moisture

- Abrasive debris from cotton fibers [1][2]

These conditions attack bearings relentlessly. Poor lubrication is a major culprit, causing parts to run dry, overheat, and fail quickly [1]. At the same time, contamination from dirt, moisture, and cotton lint gets inside bearings and grinds them down from the inside out [1][2]. Without a solid plan, mills face the same breakdowns again and again, costing them millions in lost revenue [2][1].

Understanding Bearing Failure: Root Causes and Warning Signs

In Indonesia's textile industry, a failed bearing is rarely a surprise. The real problem is that failures often happen over and over again. This is because teams replace the broken part without ever finding the root cause, making true bearing failure prevention seem impossible [8].

The issues usually come down to a few key culprits:

- Contamination: Tiny cotton fibers flying from high-speed looms and spindles are the number one enemy. They get into bearings, jam the components, and cause them to fail prematurely [8].

- Improper Maintenance: Simply swapping a failed bearing isn't enough. If the underlying issue, like an unbalanced fan or a loose bolt, isn't fixed, the new bearing is doomed to fail again within months [8].

- Constant Operation: Textile machines run almost nonstop, sometimes 364.5 days a year [8]. This intense schedule means even a tiny misalignment can quickly wear out a bearing.

Spotting trouble early is a core part of smart bearing maintenance. While many wait for a complete breakdown, proactive teams look for subtle clues. Instead of just reacting, a modern approach for industrial maintenance Indonesia involves training technicians to identify the precursors to failure before they shut down a production line [8].

The harsh environment of heat, dust, and humidity only makes things worse. Cotton dust is the main contaminant that clogs bearings and interferes with proper lubrication [8]. In areas like Jakarta, the combination of nonstop machinery and environmental stress drastically shortens bearing life. However, mills that adopt a comprehensive maintenance program have been able to reduce their bearing consumption by an incredible 48% [8].

Lubrication Strategies That Work in Indonesia’s Harsh Climate

The right lubrication is the most important factor for bearing failure prevention in Indonesia’s harsh climate. In an environment with extreme heat, constant dust, and non-stop operations, choosing the correct grease and applying it properly is essential for keeping machinery running [15].

First, always stick to the lubricants recommended by your bearing’s manufacturer. Brands like NTN, KOYO, or NSK are specifically engineered for the heavy loads and high temperatures common in Indonesia's textile industry [15]. Be careful not to use too much or too little; dry bearings are a major warning sign of grease depletion and upcoming damage. In mills heavy with cotton fibers, like Gul Ahmed, consistent lubrication combined with good cleaning habits is key to stopping debris from jamming the parts [15][16]. High-quality seals are also your best friend, as they protect bearings from the dust and moisture that are everywhere [15][16].

Next, forget fixed calendar schedules for re-lubrication. For effective industrial maintenance Indonesia, you need a more flexible approach.

- Monitor your machines: Base your re-lubrication schedule on actual operational hours or data from condition monitoring [15].

- Perform monthly checks: Look for signs of dryness, rising temperatures, or debris buildup to stay ahead of problems [15][16].

- Adapt to the season: Indonesia’s intense summer heat and dusty conditions demand more frequent attention than other times of the year.

This proactive method is a core part of modern bearing maintenance and is what allows high-uptime plants to run almost year-round without major issues [16].

Finally, proper lubrication directly impacts your bottom line. By reducing friction, it boosts machine efficiency and slashes operational costs by preventing surprise breakdowns [15]. This is critical for supporting the 24/7 operations of air jet looms and spindles, where a single failure can halt production [15][16]. When combined with good seals and correct load limits, the right lubrication strategy maximizes the lifespan of your bearings and ensures long-term profitability [15].

Contamination Control: Keeping Bearings Clean and Functional

The biggest enemy of your bearings isn't heavy loads; it's tiny particles of dust and dirt. In Indonesia's textile industry, contamination is one of the top reasons bearings fail long before they should [22][23]. When dirt gets inside, it mixes with the lubrication and acts like sandpaper, grinding away at the metal. This is why effective bearing failure prevention starts with keeping things clean.

It happens easily. A poor seal, dirty tools, or even installing a bearing in a dusty area can introduce contaminants that destroy it from the inside out [22].

So, how do you stop it?

- Use the Right Seals: Make sure your bearings have effective seals, like the 2RS type, which are designed to block out dirt and moisture [22]. Always check that existing seals are in good shape and not cracked or worn out [23].

- Add Extra Shields: For extremely dusty areas (think of a typical mill in Bandung), adding extra shielding around the bearing housing gives you another layer of defense [22].

- Keep Your Workspace Clean: This is a core part of good bearing maintenance. Always use clean tools and fresh, clean lubricant when handling or installing bearings [22]. A little bit of prep goes a long way.

A simple routine is key for industrial maintenance Indonesia. Schedule monthly checks to look for debris buildup or leaks around the bearings [23]. Training your team to spot these issues and understand the importance of cleanliness can prevent surprise failures across all your machinery [24].

Seasonal Maintenance Planning: Adapting to Indonesia’s Climate

In Indonesia’s textile industry, the weather is a huge factor. With scorching summers over 40°C and cooler winters, your machinery faces extreme stress that speeds up bearing wear [31][32]. Adapting your bearing maintenance plan to the seasons is the secret to bearing failure prevention and keeping your mill running smoothly.

This is what smart industrial maintenance Indonesia looks like in action.

Summer Checklist: Beat the Heat and Dust

When temperatures soar, grease thins out and dust gets everywhere. Your goal is to fight back.

- Increase Lubrication: Your machines are thirsty. Re-grease bearings more often, maybe every 100-200 hours, using a high-quality, heat-resistant grease [31]. Proper lubrication is your first line of defense.

- Check Seals Daily: Dust and cotton fibers are killers. Inspect seals every day to make sure they are not letting contaminants in that can jam the bearings [31][32].

- Monitor Temperature: Use an infrared thermometer to check bearing temperatures. If a bearing is running too hot, it’s a clear sign of a problem like inadequate lubrication or overload [31].

Winter Checklist: Fight Moisture and Cold

Cooler weather brings its own set of challenges, mainly around moisture and thick grease.

- Verify Grease Levels: Cold can make grease thicker, leading to dry spots. Check at least once a month to ensure bearings have enough grease to operate without friction [31].

- Inspect for Moisture: Check seals for any signs of water getting in, which can cause rust and failure. In very humid areas, consider using stainless-steel bearings [31].

- Manage Load Changes: Avoid sudden changes in machine load. Cold metal contracts, and sudden stress can cause damage [31].

A good preventive maintenance routine combines these seasonal checks with year-round monitoring. Regular inspections for cracks, unusual noises, and leaks are essential [31]. By tailoring your maintenance to the local climate and controlling contamination with tools like overhead vacuums, you can stop problems before they start [31][32]. Using reliable bearing brands like NTN or NSK, known for handling extreme conditions, can further reduce downtime and save costs [31][35][38].

Cost-Saving Benefits of Proactive Bearing Maintenance

Waiting for a machine to break is the most expensive way to run your facility. A proactive bearing maintenance plan saves you a huge amount of money by stopping problems before they start, especially in the demanding textile industry [39]. Instead of paying for emergency repairs and losing money every minute a machine is down, you stay ahead of the game.

The secret is focusing on bearing failure prevention. This means doing the simple things right:

- Proper Lubrication: Following the manufacturer's guide for lubrication is non-negotiable. It prevents the friction that leads to damage and signals when a bearing needs attention [39].

- Contamination Control: In a dusty textile mill, dirt and fibers are your enemy. Using high-quality seals and checking them often keeps contamination out of your bearings [39].

- Correct Operation: Make sure you are not overloading machines. Monitoring temperature can also give you an early warning that something is wrong, like not enough lubrication [39].

Just look at Gul Ahmed Textile Mills Ltd. They partnered with SKF to overhaul their maintenance strategy back in 1998 [40]. Instead of just fixing bearings that jammed with cotton fibers, they found the root causes, like unbalanced fans or loose bolts. By fixing the real problems, they stopped the same breakdowns from happening over and over, which boosted the entire plant's productivity [40].

Implementing a structured program for industrial maintenance Indonesia provides a clear return on investment. Every minute of unplanned downtime is lost revenue [40]. By using durable parts, like Japanese bearings known for their strength, and adopting a proactive approach like Gul Ahmed, you slash surprise repair bills and extend the life of your equipment [39][40]. This simple shift from reactive to preventive maintenance keeps your machines running and money in your pocket.

Key Takeaways: What Every Mill Supervisor Should Remember

Effective bearing maintenance is the key to uptime in the textile industry. To make bearing failure prevention a reality in your facility, focus on these core practices.

Here are the top five tips to remember:

- Correct Installation: Always select the right bearing and ensure it is installed with proper alignment [46].

- Consistent Lubrication: Follow the manufacturer's guidelines for the type, amount, and frequency of lubrication [46].

- Contamination Control: Protect bearings with high-quality seals to block out dust, moisture, and cotton fibers [46][47].

- Avoid Overloading: Operate machinery within its designed load limits to prevent premature wear [46].

- Proactive Inspections: Check for cracks, leaks, high temperatures, and unusual noises every month [46][47].

For daily routines, use this simple checklist:

- Check lubricant levels and re-lubricate based on operational hours to avoid dry bearings [46].

- Inspect seals regularly to ensure they are blocking dirt and debris effectively [46][47].

- Listen for unusual noises and monitor for overheating, as these are early signs of failure [46].

Finally, industrial maintenance Indonesia must adapt to our climate. The extreme heat and constant dust demand a smarter strategy. This includes using climate-specific lubricants and implementing programs that find the root cause of failures, preventing them from happening again and saving you from costly downtime [46][47].

Citations:

[1]: https://matraderss.com/japanese-bearings-pakistan/

[2]: https://evolution.skf.com/textiles-with-a-global-spin/

[3]: https://universaltradings.com/finishing-textile-machines/

[4]: https://dpibearings.com/?page_id=235

[5]: https://hyderali.com/about-us/

[6]: https://universaltradings.com/textile-machines/

[7]: https://orbitoglobal.com/industrial-bearing/

[8]: https://evolution.skf.com/textiles-with-a-global-spin/

[9]: https://universaltradings.com/finishing-textile-machines/

[10]: https://dpibearings.com/?page_id=235

[11]: https://hyderali.com/about-us/

[12]: https://universaltradings.com/textile-machines/

[13]: https://orbitoglobal.com/industrial-bearing/

[14]: https://www.sacotraders.com/nsk.htm

[15]: https://matraderss.com/japanese-bearings-pakistan/

[16]: https://evolution.skf.com/textiles-with-a-global-spin/

[17]: https://universaltradings.com/finishing-textile-machines/

[18]: https://dpibearings.com/?page_id=235

[19]: https://hyderali.com/about-us/

[20]: https://universaltradings.com/textile-machines/

[21]: https://orbitoglobal.com/industrial-bearing/

[22]: https://hitecbearings.id/blog/troubleshooting-angular-contact-bearings-a-guide-for-industries/

[23]: https://matraderss.com/japanese-bearings-pakistan/

[24]: https://evolution.skf.com/textiles-with-a-global-spin/

[25]: https://universaltradings.com/finishing-textile-machines/

[26]: https://universaltradings.com/textile-machines/

[27]: https://dpibearings.com/?page_id=235

[28]: https://hyderali.com/about-us/

[29]: https://orbitoglobal.com/industrial-bearing/

[30]: https://www.sacotraders.com/nsk.htm

[31]: https://matraderss.com/japanese-bearings-pakistan/

[32]: https://evolution.skf.com/textiles-with-a-global-spin/

[33]: https://universaltradings.com/finishing-textile-machines/

[34]: https://dpibearings.com/?page_id=235

[35]: https://hyderali.com/about-us/

[36]: https://universaltradings.com/textile-machines/

[37]: https://orbitoglobal.com/industrial-bearing/

[38]: https://www.sacotraders.com/nsk.htm

[39]: https://matraderss.com/japanese-bearings-pakistan/

[40]: https://evolution.skf.com/textiles-with-a-global-spin/

[41]: https://universaltradings.com/finishing-textile-machines/

[42]: https://dpibearings.com/?page_id=235

[43]: https://hyderali.com/about-us/

[44]: https://universaltradings.com/textile-machines/

[45]: https://orbitoglobal.com/industrial-bearing/

[46]: https://matraderss.com/japanese-bearings-pakistan/

[47]: https://evolution.skf.com/textiles-with-a-global-spin/

[48]: https://universaltradings.com/finishing-textile-machines/

[49]: https://dpibearings.com/?page_id=235

[50]: https://hyderali.com/about-us/

[51]: https://universaltradings.com/textile-machines/

[52]: https://orbitoglobal.com/industrial-bearing/

[53]: https://matraderss.com/japanese-bearings-pakistan/

[55]: https://evolution.skf.com/textiles-with-a-global-spin/

[56]: https://universaltradings.com/finishing-textile-machines/

[57]: https://dpibearings.com/?page_id=235