# The True Bearing Cost Destroying Your Manufacturing ROI: Why a Quality Bearings Industrial Investment Is Crucial for Equipment Reliability Indonesia

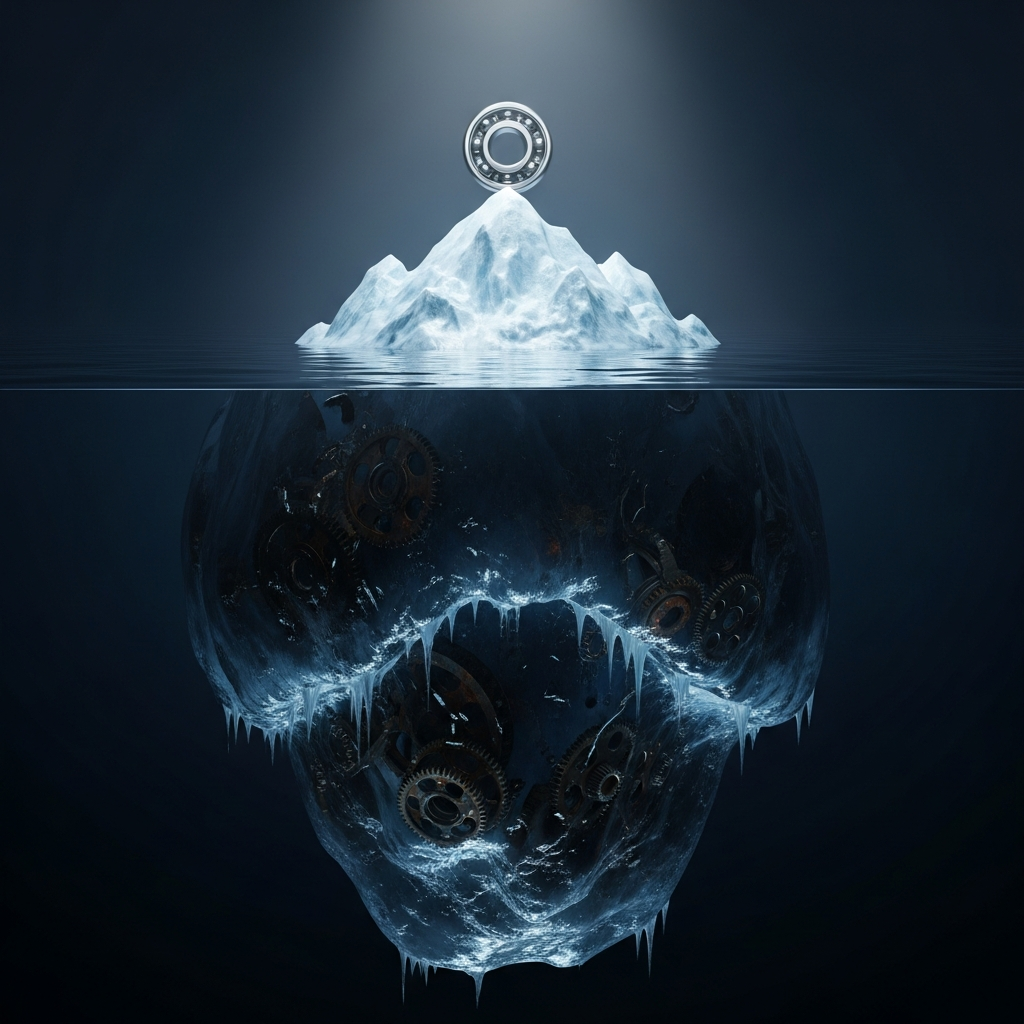

That cheap bearing you bought for a few hundred rupees isn't a bargain. It’s a trap, and it’s quietly destroying your entire operation by inflating your true bearing cost.

Every time one of those budget parts fails, your production line grinds to a halt, killing your manufacturing ROI. This is the frustrating cycle that undermines equipment reliability Indonesia factories face every single day. You end up losing more money in a single hour of downtime than you "saved" on that cheap part in the first place.

This guide will show you how to stop the bleeding. We will prove that choosing the right component is a serious industrial investment, not a minor expense.

We’ll break down the numbers to show you exactly how much a cheap part really costs you in repairs and lost production. You'll also see why investing in quality bearings is the single smartest decision you can make for long-term profitability.

Introduction: The Hidden Cost Manufacturers Can't Ignore

In Indonesia's manufacturing world, the real bearing cost is not what you pay upfront; it's the massive expense of downtime and lost production when cheap parts fail. Managers often see a bearing for as low as PKR 215 and think they've found a bargain [3]. Some imports from China are even cheaper, costing just a few cents per piece [1][2]. But this is a trap that destroys your manufacturing ROI.

Every time one of these low-cost bearings breaks, your production line can grind to a halt. This is the hidden cost of poor equipment reliability Indonesia factories face daily. The money lost from a single hour of stopped production is often far more than what you would have spent on quality bearings from trusted brands like NTN or SKF in the first place [3][5].

This article will show you why choosing the right bearing is a serious industrial investment, not just a small purchase. We'll break down how cheap parts cause losses from emergency fixes and halted production, proving that reliable components are the smarter, more profitable choice for any factory [6][7].

What Is the True Bearing Cost in Indonesian Manufacturing?

The true bearing cost in Indonesia is not the price on the box; it's the total expense of downtime, repairs, and lost production when a cheap part fails. Many factory owners look at a bearing priced at ₨250 and compare it to one costing ₨20,000, thinking they are saving money [11][12][13]. This is a major mistake that hurts your manufacturing ROI.

Let’s break down the real costs you might be overlooking.

The Hidden Costs of a "Cheap" Bearing

Think about what happens when a low-cost bearing gives out. It’s never just about replacing the part. The total cost includes:

- Frequent Replacements: Buying the same cheap part over and over again.

- Maintenance Labor: Paying your team to stop production and fix the same machine repeatedly.

- Production Downtime: This is the biggest killer. Every hour your line is stopped, you are not making products or money. This directly destroys your profit margins.

- Damage to Other Parts: A failing bearing can cause a chain reaction, damaging more expensive components of your machinery.

Improving equipment reliability Indonesia starts with understanding that a bearing is not just a part, it's a critical industrial investment.

A Simple Factory Example

Imagine a production line in Bandung that runs 10 hours a day.

- Scenario 1: The Cheap Bearing

- Upfront Cost: ₨1,000 for a budget bearing [9][15].

- Lifespan: It fails every 3 months.

- Downtime: Each failure stops production for 4 hours.

- Annual Cost: Over a year, that’s 4 failures. That’s 16 hours of lost production, plus the cost of 4 bearings and the labor to install them. The initial bearing cost was low, but the total loss is massive.

- Scenario 2: The Quality Bearing

- Upfront Cost: ₨15,000 for a high-performance SKF or FAG bearing [12][14].

- Lifespan: It is rated to last for 2 years under the same conditions.

- Downtime: Zero unexpected failures for 24 months.

- Annual Cost: Just the initial purchase. The factory experiences zero downtime from this part, maximizing production and profit.

In this example, choosing quality bearings saved the factory from costly production stops and protected its manufacturing ROI. The more expensive bearing was actually the cheaper option in the long run.

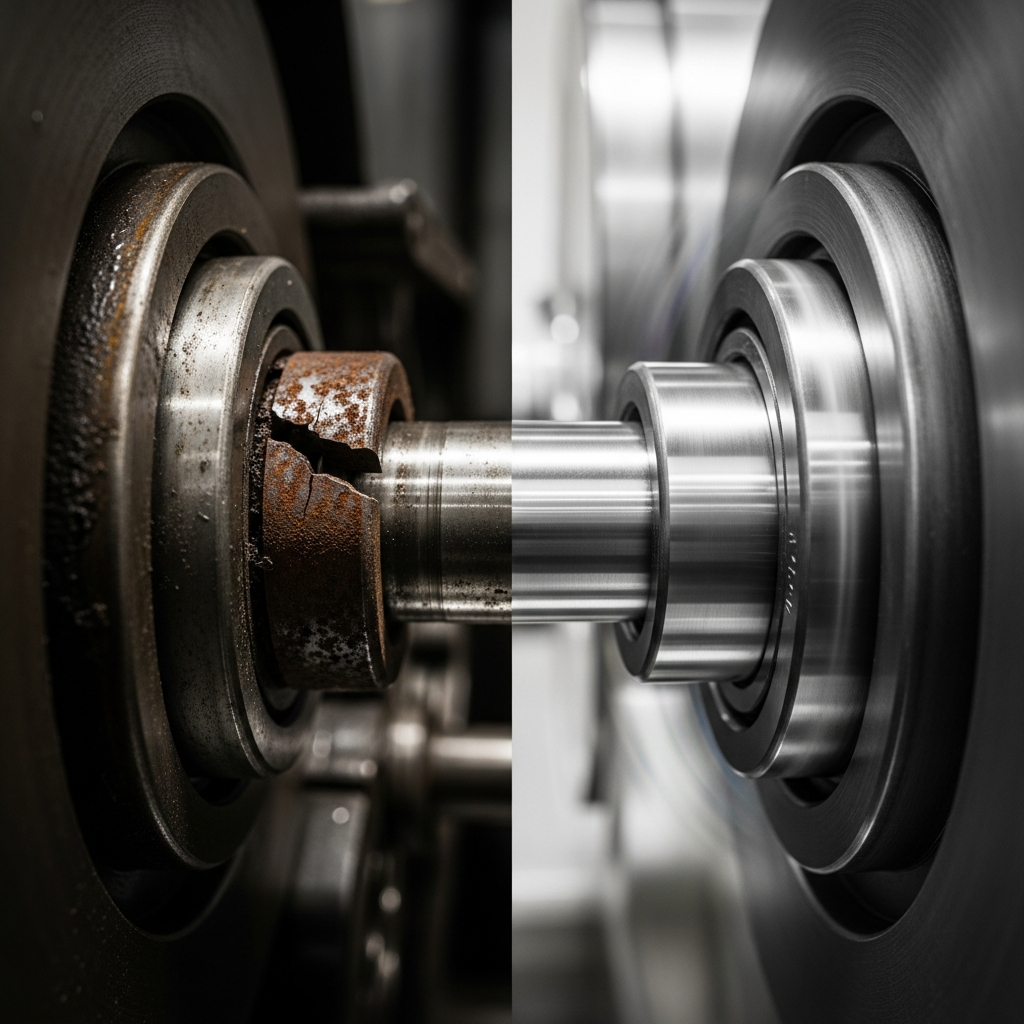

How Cheap Bearings Undermine Equipment Reliability in Indonesia

Cheap bearings destroy equipment reliability Indonesia by failing quickly under normal industrial stress, leading to constant machine breakdowns and expensive downtime [17][16]. While a price tag as low as $0.10 per piece seems like a great deal, these parts are often made with weak metals and poor precision [17]. They simply can’t handle the heat, dust, and vibrations common in Indonesia's manufacturing plants, causing them to seize up and damage other critical machine parts [18][20].

Let's look at a real-world example. A factory might save a few rupees buying bearings for $0.60 to $0.70 each. But when those bearings fail every few months, the factory faces repeated shutdowns. Each breakdown can cost between ₨50,000 and ₨100,000 in repairs, not to mention the lost production time [17][22]. Suddenly, that initial saving is wiped out. The true bearing cost isn't the purchase price; it's the endless cycle of repairs and replacements.

This is where the math becomes very clear.

- The Loss: A single day of stopped production can cost a factory ₨200,000 to ₨500,000 [18][19][20].

- The Solution: A premium quality bearings from a trusted brand like NTN or SKF might cost ₨400 but can last for years, not months [18].

Choosing a better bearing isn't an expense, it's a smart industrial investment. By spending a little more upfront, you drastically cut down on failures, boost your manufacturing ROI, and achieve the long-term savings that keep your business running smoothly [16][23].

Quality Bearings as Smart Industrial Investment

Viewing quality bearings as a smart industrial investment is the first step to improving your factory's performance. Cheap, unbranded bearings often fail under high-load applications, leading to sudden and costly breakdowns [24][27][31]. This is a huge threat to equipment reliability Indonesia. By choosing trusted brands like SKF, NTN, and NSK from reliable suppliers such as SABCO Traders or Industrial World, you get parts designed to handle heavy radial and axial loads, which cuts your long-term operational risks [24][27][29][31].

Calculating the return is simple. While a premium bearing like an NTN 6204-2RS might cost Rs 310, it prevents thousands in losses from halted production [27]. The initial bearing cost is tiny compared to the gains in your manufacturing ROI. Premium bearings last much longer, meaning fewer replacements and less downtime [24][26][27]. Indonesia's average export price for bearings was $37,443 per ton in 2024, showing the market values premium products that lower the total cost of ownership [30].

In Indonesia, suppliers like Hi-Tec, SABCO Traders, and Industrial World are leading this change [24][27][28][29][31]. They offer genuine Japanese and European bearings, moving manufacturers away from risky, cheap imports found on sites like Alibaba [25][26][31].

Don't just take our word for it. One factory owner shared his experience:

> "After constant breakdowns with budget bearings costing us weeks in downtime, we switched to SKF and NTN... our machines now run 3x longer, slashing replacement costs by 40% and doubling output. Quality pays back fast in Indonesia's tough manufacturing environment." [27][31]

Common Myths About Bearing Cost and Manufacturing ROI

Let's clear up some costly mistakes. Many factory managers believe that cheaper bearings save money, but this thinking destroys your manufacturing ROI.

It’s easy to see a bearing for Rs 70 and think you’re getting a deal [37]. But that low upfront price is a trap. These cheap parts fail quickly, leading to constant machine downtime, repair labor, and replacement orders. This hidden spending makes the true bearing cost much higher in the long run [32][33][34].

- Myth 1: A lower price means a lower bearing cost.

This is not true. A generic bearing imported for $0.10 is not the same as a premium SKF or NTN bearing [34][39]. Quality bearings are engineered with specific features, like special shielding or C3 clearance, to handle heavy loads and tough conditions [35][36]. They are built for reliability, while budget options are not [35][36][39].

- Myth 2: All bearings do the same job.

The reality is that your choice is a serious industrial investment. In a market where Indonesian exports can average $37,443 per ton, machine uptime is everything [38]. Better equipment reliability Indonesia depends on using parts that last. Spending Rs 335 on a genuine SKF bearing prevents breakdowns that cost thousands in lost production, while a cheap alternative invites disaster [32][35][36][39]. Prioritizing quality over upfront price is the only way to protect and improve your manufacturing ROI [32][34][38].

Citations:

[1]: https://www.alibaba.com/showroom/pakistan-bearing.html

[2]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[3]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[4]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[5]: https://bearingpk.com/product-category/ball-bearing/single-row-ball-bearing/

[8]: https://wellshop.pk/search/ntn-bearing/

[9]: https://www.alibaba.com/showroom/pakistan-bearing.html

[10]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[11]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[12]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[13]: https://bearingpk.com

[15]: https://sabcotraders.com

[16]: https://www.alibaba.com/showroom/pakistan-bearing.html

[17]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[18]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[19]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[20]: https://bearingpk.com/product-category/ball-bearing/single-row-ball-bearing/

[22]: https://bearingpk.com

[23]: https://wellshop.pk/search/ntn-bearing/

[24]: https://industryparts.pk/collections/bearing

[25]: https://www.alibaba.com/showroom/pakistan-bearing.html

[26]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[27]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[28]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[29]: https://bearingpk.com

[31]: https://sabcotraders.com

[32]: https://industryparts.pk/collections/bearing

[33]: https://www.alibaba.com/showroom/pakistan-bearing.html

[34]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[35]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[36]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[37]: https://bearingpk.com

[39]: https://sabcotraders.com

[40]: https://industryparts.pk/collections/bearing

[41]: https://www.alibaba.com/showroom/pakistan-bearing.html

[42]: https://www.made-in-china.com/products-search/hot-china-products/Ball_Bearing_Indonesia.html

[43]: https://onlinestore1.industrialworld.com.pk/product-category/bearings/deep-groove-ball-bearings/

[44]: https://instock.pk/skf-spherical-roller-bearing-22316e-c3.html

[45]: https://bearingpk.com

[47]: https://sabcotraders.com